What You Need to Know

What Are Standards of Identity?

A “standard of identity” is an agreed upon legal definition for what a food actually is. Standards of identity were introduced as a means of consumer protection. Although “common name” is the most applicable facet of Standards of Identity, there are actually three components to consider:

Common Name (Identity): The standardization and definition of common food names ensures that consumers know what a food product actually is. Typically, the common name is required to be written on the label of a food container.

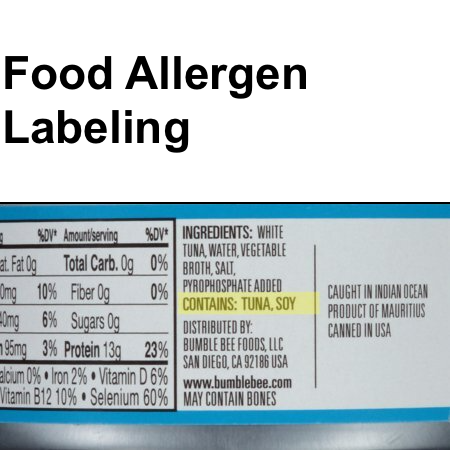

Example: A food marketed as “canned tuna” must legally be tuna and not some other fishStandard of Quality: The food meets certain quality standards described in the regulations for that standardized food. (This doesn’t apply to most foods).

Example: A food marketed as canned tuna cannot contain ingredients or additives that the consumer would not typically associate with canned tunaStandard of Fill of Container: The packaging contains a minimum fill defined for that standardized food. This doesn’t apply to most foods)

Example: If canned tuna is advertised as 8oz of canned tuna in broth, then you are getting 8oz of tuna and not 7oz of broth and 1oz tuna.

Does My Food Product Have a Standard of Identity?

The best way to find out what the regulatory requirements are for your particular food product is to understand exactly which one of the following groups it falls into:

1. Foods for which there categorically is no definition or standard of identity

According to the FD&C act, no standard of identity or definition may be established for:

Fruits (fresh and dried)

Vegetables (fresh and dried)

Avocados,

Cantaloupes

Citrus fruits

Melons

This means there’s no specific definition for what is an apple and it means there’s no regulation that the word “apple” must appear on an apple that is being sold. If you produce a product that falls into this category, then you don’t need to be particularly concerned about misbranding your product due to standards of identity/definitions.

2. Non-standardized foods subject to specific requirements

These foods don’t have standards of identity per se, but they are subject to some requirements. You can quickly review this small list of foods in 21 CFR Part 102.

If the food you produce falls into this category, then it’s important to understand these requirements, but otherwise your product is not a standardized food.

3. Standardized Foods (Foods which have a standard of identity)

These are foods that the FDA has decided to define because there is a public expectation of what that food is . Anyone who makes a” standardized” food must make sure it satisfies the standards outlined for that food. These requirements range from mandated ingredients to packaging standards, to banned ingredients.

The categories for all standardized foods are listed in the sidebar to the right.You can also access these categories in CFR Parts 131-170

4. Non-standardized foods

These are foods that simply are not addressed in any of the sections referenced above. Since they are non-standard then they don’t have specific requirements for calling your food that name. Non-standardized foods must be labeled using the common or usual name for that food.

Many innovative products fall into this category. However, if you wish to market your product as something for which there is a standard of identity, then you must adhere to those standards or market your product differently.

For example, if you make a fermented chia-seed snack food that you wish to market as Chia Yogurt, then you must comply with the standards of identity definition for “yogurt” —since that’s how you are marketing the product. If your product is categorically unfit to meet the definitions of yogurt, then you may consider marketing it using descriptive terms (i.e. “fermented, plant-based snack food).

Identity Labeling Requirements

Packaged foods must be labeled with the product’s identity (common name). The requirements are as follows:

The statement of identity must be presented in bold type on the Principal Display Panel

If the food is marketed in multiple forms (i.e. whole, sliced, diced) then the form of the product is deemed to be part of the statement of identity

Formatting:

The text must be bolded and in a size “reasonably related to the most prominent printed matter on the panel”

The wording must be parallel to the base of the packaging so it reads normally when displayed (not sideways or upside down).

Less Common Requirements:

Dietary supplements must be identified in the identity statement in one of three ways:

Using the term “dietary supplement”

Using the convention “[nutrient name] supplement” (i.e. “Iron supplement)

Using a descriptive term indicating the ingredients in the product (i.e. herbal supplement with vitamins)

Substitution or imitation foods must be identified as such in the identity statement (i.e. imitation crab) A substitute food resembles another food and is meant to substitute it. An imitation food is the same except that it is nutritionally inferior to the food it imitates.

FAQ

What if My Product Doesn’t Have A common Name Because It’s an Innovative PRoduct?

In that case, you may use a descriptive term in the identity statement

What if My Product falls under a Standard of Identity but fails to meet the regulated standard?

A food producer may apply for a Temporary Marketing Permit (TMP) which allows them to sell their product for 15 months even though it may not confirm to some art of the applicable “standard of identity”.

For example, according to the FDA, Canned Pacific Salmon can only contain pacific salmon, water, and salmon oil.

In 1988, Bumblebee applied for a TMP which would allow them to add a tasteless, odorless preservative called sodium tripolyphosphate to the product. Normally, Bumblebee would not be allowed to sell the product as Canned Pacific Salmon, since the product would not fit the standard of identity.

However, the TMP gave them the permission to temporarily circumvent the standard of identity and sell their product (it’s worth nothing that sodium tripolyphosphate was an allowable food additive at that point.)

Food Categories with Regulated Definitions: